First Fogra PSD certification in Croatia

Graficki studio 5 do 12 is the first print shop in Croatia and the region that is certified with the renowned Fogra ProcessStandard Digital (PSD).

Graficki studio 5 do 12 is the first print shop in Croatia and the region that is certified with the renowned Fogra ProcessStandard Digital (PSD).

Share the News: Weatherford, Oklahoma is the location of Kodak’s latest capital investment, a new FLEXCEL NX plate line.

Brixen, Italy – 05/15/2017 – Durst, manufacturer of advanced digital production technologies, is successfully continuing the roadmap set for its business segment Durst Corrugated Packaging & Display Printing, which it established in 2016. Following successful installation of its Delta WT 250 multi-pass printing system with Durst Water Technology for a number of customers at the beginning of the year, Durst is now field-testing its flagship system, the Delta SPC 130.

MPI Label Systems, headquartered in Sebring, OH, operates from 11 plant locations across the US (OH, CA, CT, MD, IL, TX,NC, TN & NY), each working together for fulfilling the overall MPI commitment of high service, outstanding quality, integrity, customer satisfaction, and innovation. The company's Wadsworth, OH facility, now known as MPI/Labeltek, was formed as a result of MPI acquiring Labeltek’s business nearly four years ago.

Durst, the industrial inkjet specialist, and new partner Wifac, the company with expert label and packaging knowledge, have announced their first customer cooperation deal across BENELUX for the Tau 330E UV digital inkjet press.

The Label Collective Group at Haaksbergen, The Netherlands, which employs 35 people, has high expectations for the Tau 330E solution. Live production has started this week. It will help to open new markets and further accelerate its fast-growing business in labels.

Durst unveils its new corrugated packaging & display printing segment

with single-pass and multi-pass technologies, along with its successful Tau 330 Portfolio for label production

Kodak saw the volume of Sonora process free plates in the market grow by 50 percent in 2015, driven by increasing industry demanding for sustainable printing.

Sonora plate production facilities are located in the USA, Europe and China, serving more than 3,000 customers worldwide. Kodak said this global footprint has allowed customers across the world to realize the economic and environmental benefits of Sonora plates, which deliver the print capabilities and productivity of mainstream plates without the processing and chemistry.

At KODAK, we’re breaking barriers... again! We’re adding new features to our Unified Workflow Solutions... features to help you meet the challenges of the ever-changing print industry. Features like:

You can be among the first to see the new PRINERGY Workflow in action.

|

At drupa 2016, we’re giving personal demonstrations of some of the powerful new features of our Unified Workflow Solutions… capabilities that drive costs down and help printers like you compete in today’s market.

Only a few demonstration slots are left. Book yours today!

See how the PRINERGY Cloud Service puts business efficiency first, with:

Digital UV inkjet label printing has reached the point of full market readiness. It impresses with its handling of small and medium-sized print runs and offers new applications for primary packaging

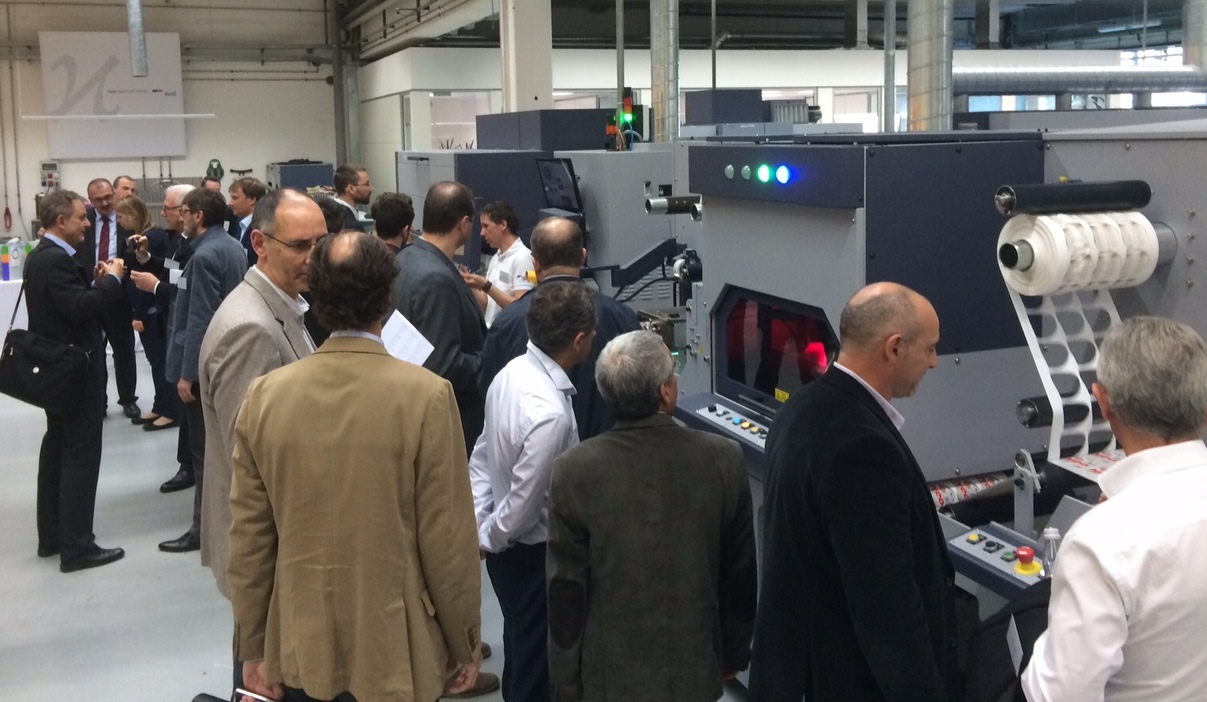

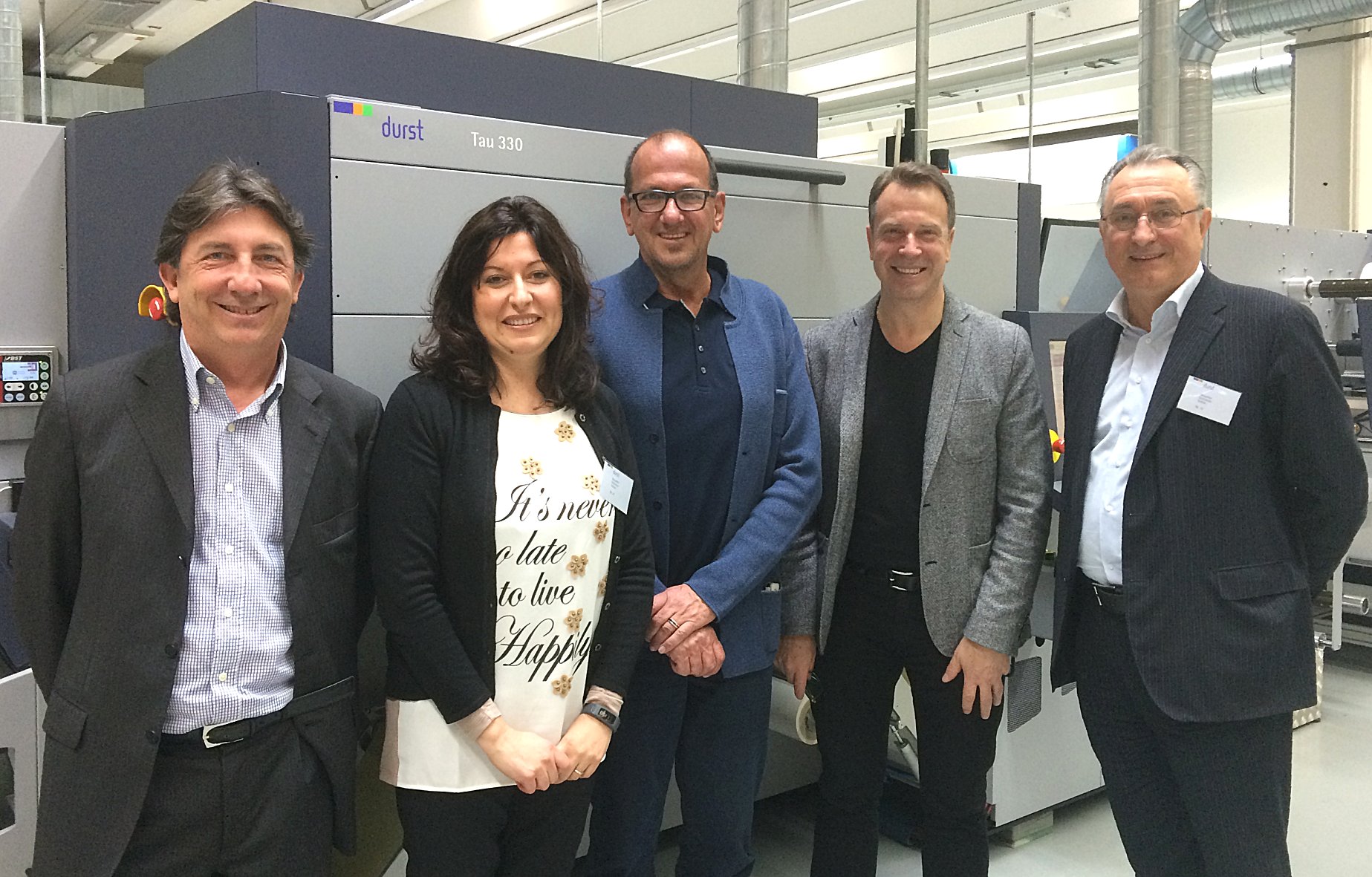

Durst, specialist in industrial inkjet applications, presented the latest developments in label printing for the label and packaging industry from April 14th – 16th at "Digital Days 2015" in Brixen, Italy. More than 150 participants from three continents participated in the 3-day event. Helmuth Munter, Segment Manager of Durst Labels & Package Printing, led the varied program of events, which included guest speakers from Rako Etiketten, TLF Graphics, Sunjet and Spartanics. The main focus was on digital advancements with the Tau 330, new applications with low-migration inks and workflow automation with the laser finishing system. Another focus was digital market potential in the packaging industry, followed by a look ahead to Labelexpo Europe 2015.

Perfect integration with other equipment for diverse printed label requirements

Durst, the industrial inkjet specialist andLabel-form Ltd, based in Maidenhead in the UK, recently decided to install a Durst Tau 330 digital UV Inkjet Label Press to expand the digital production capacity of this leading label printing specialist. The company refers to it as ‘a new level of digital print’.

Always at the forefront of new developments, Label-form wanted to increase its digital production. “Many customers come to us because of the colour density and white we normally offer with screen printing,” Stewart Serls, Sales Director of Label-form, explained. “The colours and white produced by the Durst are absolutely fantastic, one of the main reasons why we opted for the Tau 330.”

Italian Tau 150 customer invest in the new UV Inkjet label Press Tau 330;

Durst, the industrial inkjet specialist and the Italian company Poliweb Graphics S.r.l.(PWG) are intensifying their cooperation by installing the new digital UV Inkjet Label Press Tau 330. PWG designs and produces innovative packaging solutions: standard and multi-paged self-adhesive labels with special technological solutions and informative booklets. In late 2011, PWGinstalled the Tau 150 Label Printer, in order to open up new market potential with digital label production.